Triumph TR Design & Manufacturing Facilities

Expert In-House Design Using CAD

At Racetorations, we specialise in designing high-quality parts for Triumph TR vehicles. All our products are crafted in-house using the latest 3D computer-aided design (CAD) software.

Our advanced CAD technology enables us to create precise and detailed models, ensuring accuracy and functionality from the outset. Our skilled team leverages CAD to explore innovative solutions and optimise designs for superior performance and durability.

3D Printing for Prototyping

Before we move to final manufacturing, we use 3D printing technology to produce prototype models.

This crucial step allows us to:

- Physically inspect the design

- Test its fit and functionality

- Make any necessary alterations

By identifying potential issues early in the design process, we ensure that the final product meets our stringent quality and performance standards.

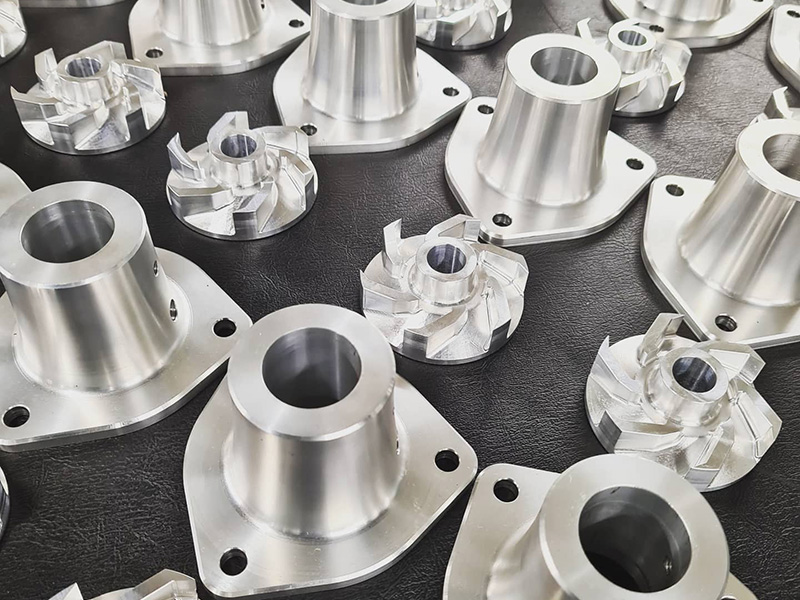

Local Manufacturing Partnerships

Once a design is finalised, we collaborate with a trusted network of local engineering firms to manufacture the items. Our partners are handpicked based on their expertise and their ability to meet Racetorations’ rigorous standards.

Each part is produced under the strict oversight of our team, ensuring consistency and reliability across our entire product range. This close collaboration guarantees that every item we produce adheres to the high standards you expect.

Whether you need a one-off piece or a large production run,

Racetorations is here to help.

Our expert team offers tailored advice and solutions to meet your specific design and manufacturing requirements.

If you have a part that needs drawing up or manufacturing, don’t hesitate to reach out. Contact us today to discuss your project and discover how our services can bring your Triumph TR designs to life.