Our Services

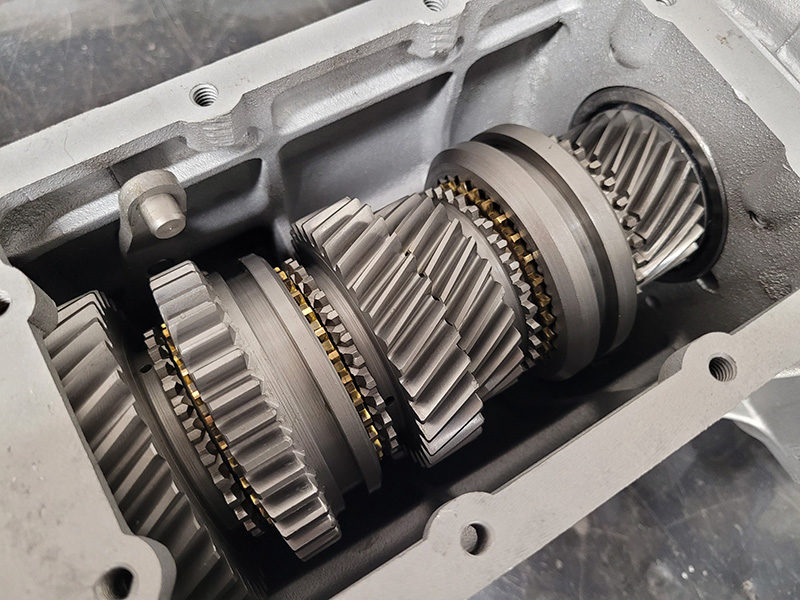

Engines, Gearboxes & Axles

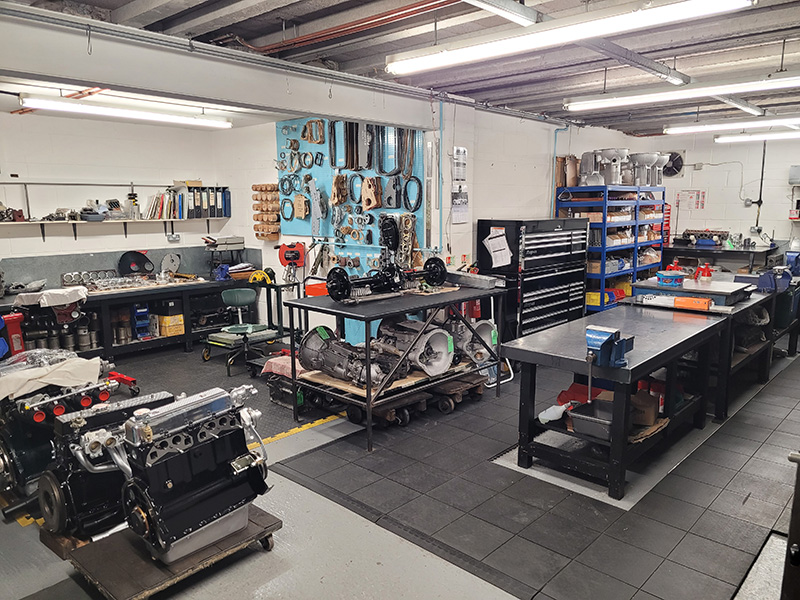

Racetorations, has a worldwide reputation for the highest standards in engine, gearbox & axle rebuilds. Our dedicated workshop houses state-of-art equipment to enable us to achieve high standards in cleanliness & automotive engineering. Each component fitted into our builds is of the highest quality with most being designed & manufactured by us or subcontracted to known & trusted suppliers. Whether it be a full rebuild, partial build or supplying the parts we can cater for all requirements.

Each engine, gearbox or axle is built to the requirements of the customer with guidance from us. We have over 100 years of combined TR experience and understand the areas that lend themselves to improvements, performance & reliability. Each customer has the option for their engine to be tested & tuned on the dynamometer before being signed off. Engines, gearboxes, overdrives and axles/differentials can also be built as ‘stand-alone’ units, fitted to customers TRs and run in which would incorporate final road tuning. We regularly ship engines, gearboxes & axles around the world in bespoke, secure crates.

Chassis Jigging & Strengthening

The chassis is the fundamental component of a TR, if it is bent, twisted or rotten it will affect the entire feel, look and performance of the car. In house our own chassis jig enables us to check, straighten and strengthen all chassis as fitted to TR2-6’s. We use the original factory drawings for each type of chassis and work to a tolerance of +/- 1mm, a lot more precise than Triumph’s +/- 3mm when new.

With our experience in TR’s we know where chassis require strengthening and where modifications such as exhaust and cruciform clearance are needed. We can offer a full chassis rebuild including all suspension components or just a simple chassis alignment check. We also offer new chassis for the whole TR range and a service for customers requiring competition enhancements.

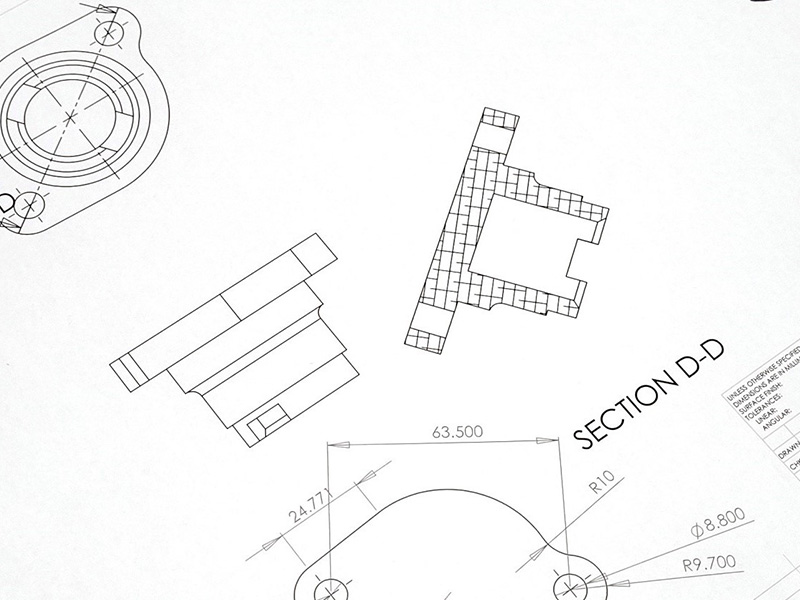

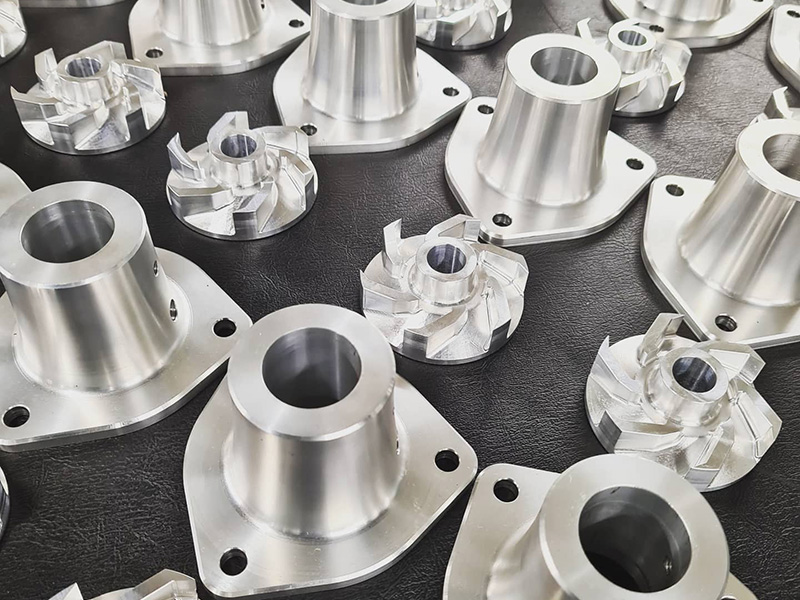

Design & Manufacturing Facilities

All our unique product range is designed in-house using modern 3D computer-aided design (CAD) software. Before final manufacturing, where possible, we produce a 3D printed model to check the design and make alterations if required. Once completed we submit the design to our local group of engineering firms to manufacture the items as required under the auspices of Racetorations.

We are happy to offer this service for one-off or large production runs of any items, if you have a part that requires drawing or manufacturing please contact us.